Viceassem screw gd is an important tool that many people use in machines and electronics. If you are new to fixing devices or working with small mechanical parts, viceassem screw gd can seem confusing at first. It is a type of screw that helps connect parts firmly, making sure everything stays in place. Many people often make mistakes when choosing or using it, which can lead to loose connections or even damage. By understanding how viceassem screw gd works, you can save time, prevent mistakes, and make your projects safer and more efficient. This guide will explain everything in a simple way, so even beginners can understand.

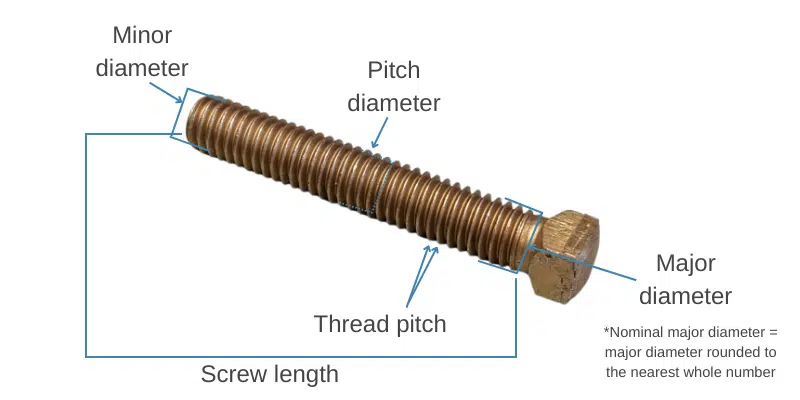

Using viceassem screw gd correctly is more than just turning it with a screwdriver. The material, size, and thread type all matter. Some viceassem screws are designed for metal, while others work better with plastic or wood. Choosing the wrong type can make your assembly weak or unstable. Additionally, the way you tighten the screw affects how strong your connection will be. Over-tightening can strip the threads, and under-tightening can make parts loose. With proper knowledge, you can pick the right viceassem screw gd for any project, know how to install it safely, and even maintain it for long-term use. By following easy steps and tips, anyone can master using this simple but essential tool.

Viceassem Screw GD: A Complete Beginner’s Guide

Viceassem screw gd is a special type of screw used in machines, electronics, and small assemblies. Many beginners and even experienced people sometimes struggle with understanding it. If you are new to tools or repairs, viceassem screw gd can seem tricky. This screw is designed to hold parts tightly and safely. Without it, many devices can become loose or stop working. In this guide, we will explain everything about viceassem screw gd in easy words. By the end, you will know how to choose it, use it correctly, and even maintain it for long life.

Using viceassem screw gd is not just about turning a screwdriver. You need to know the size, material, and type of thread. Some screws work best with metal, others with plastic or wood. If you pick the wrong one, your assembly might fail. The way you tighten it is also very important. Too tight, and the screw can get damaged; too loose, and it will not hold properly. Learning these simple tips can make your work easier and safer. Even beginners can become confident in using viceassem screw gd after reading this guide.

What is Viceassem Screw GD and Why It Matters

Viceassem screw gd is a screw that connects parts in a strong and secure way. Unlike ordinary screws, it is made for precise assemblies where strength and accuracy are very important. It is widely used in electronics, small machinery, and DIY projects. Using the right viceassem screw gd helps prevent loose connections, device failures, and safety problems.

The “GD” in its name often refers to a specific design or grade of the screw that makes it more durable. These screws are designed to last long and resist damage. Many people do not know the difference, which can cause mistakes. Knowing about viceassem screw gd helps you make better choices and avoid unnecessary costs.

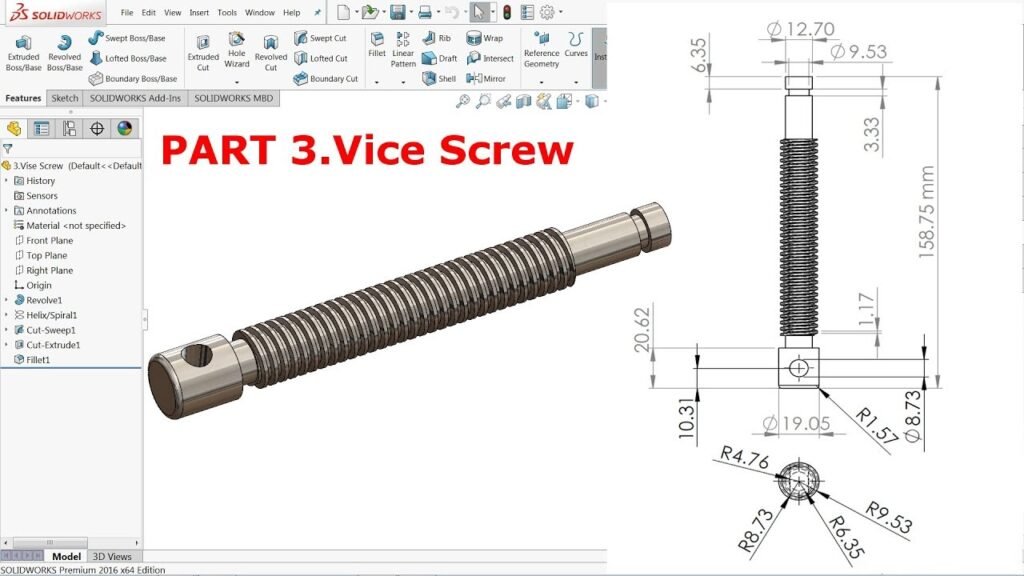

Types of Viceassem Screw GD You Should Know

There are several types of viceassem screw gd. Some common ones include:

- Standard Viceassem Screws: Used for most DIY projects and general assemblies.

- Metal-specific Screws: Made for connecting metal parts securely.

- Plastic/Soft Material Screws: Designed to hold lightweight or soft materials without causing damage.

- High-grade Screws (GD Grade): Stronger, durable, and used in precise or heavy-duty work.

Choosing the right type is very important. If you use the wrong type, your parts may not fit correctly, or the screw may break. Always check the material and size before using a viceassem screw gd.

How to Choose the Right Viceassem Screw GD for Your Project

Choosing the right screw is easy if you know a few things:

- Material of Parts: Metal, plastic, or wood – different screws work better with different materials.

- Size of Screw: Match the screw size to the hole and the parts you are joining.

- Thread Type: Fine threads for precise work, coarse threads for larger assemblies.

- Grade: GD grade screws are stronger and last longer.

By checking these points, you can be sure your assembly will be strong and safe.

Step-by-Step Guide: Installing Viceassem Screw GD Safely

- Select the Correct Screw: Make sure it matches the material and size of your project.

- Align the Parts: Hold the pieces together where they need to be fixed.

- Start Slowly: Insert the screw gently and turn it by hand at first.

- Use a Screwdriver Carefully: Turn until tight, but don’t force it. Over-tightening can strip the threads.

- Check Stability: Make sure the parts are held firmly and nothing is loose.

Following these steps will prevent damage and make your assembly strong.

Common Mistakes People Make With Viceassem Screw GD

Even experienced people make mistakes. Some common ones include:

- Using the wrong type of screw for the material.

- Over-tightening, which strips threads or breaks parts.

- Under-tightening, causing parts to be loose.

- Ignoring the GD grade and using low-quality screws.

Avoiding these mistakes saves time, money, and effort.

Tips to Maintain Your Viceassem Screw GD for Long Life

- Keep screws clean and free from rust.

- Don’t force them into the wrong holes.

- Store in a dry place to avoid corrosion.

- Use the correct tools for installation and removal.

Simple care can make your viceassem screws last much longer and work efficiently.

Viceassem Screw GD Troubleshooting: Quick Fixes

If your assembly is not holding:

- Check if the screw is the correct type for the material.

- Make sure the threads are not damaged.

- Ensure the screw is tightened properly, but not too much.

- Replace damaged screws with new GD grade screws if necessary.

These quick checks solve most problems.

Expert Advice: Using Viceassem Screw GD Like a Pro

- Always measure and select screws carefully.

- Use gentle but steady pressure when tightening.

- Match screws with the material and grade recommended for the project.

- Learn from mistakes; small errors help you understand screws better.

With practice, anyone can become skilled in using viceassem screw gd.

Conclusion

Viceassem screw gd may seem simple, but using it correctly makes a big difference in your projects. By choosing the right type, following safe installation steps, and maintaining the screws, your assemblies will last longer and work better. Even beginners can master it with these easy tips.

FAQs

Q1: What materials work best with viceassem screw gd?

A1: They work well with metal, plastic, and wood, depending on the screw type. GD grade screws are stronger and more durable.

Q2: Can I reuse viceassem screws?

A2: Yes, if the threads are not damaged and the screw is in good condition.

Q3: What happens if I over-tighten viceassem screw gd?

A3: Over-tightening can strip the threads or break the screw, making the assembly weak.

Q4: How do I know the right size to use?

A4: Measure the hole and parts carefully, and check the material type to select the correct size and thread.

Q5: Where can I buy high-quality viceassem screw gd?

A5: Look for hardware stores, electronics stores, or trusted online suppliers that provide GD grade screws.